Function and area of implementation

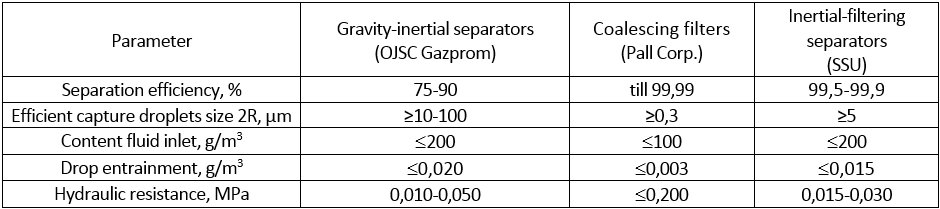

Traditional gas-separation equipment, which is used in technological lines of chemical production, has a low degree of separation (efficiency does not exceed 70%, sometimes even reaches 15-30%).

Improving the efficiency of gas separators which manufactured according to state and industry standards is possible through the application of new methods for processing gas-liquid flows and the establishment of highly effective inertial-filter separation devices with a separation efficiency of up to 99.5%.

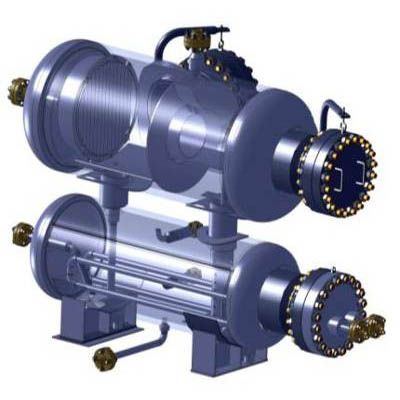

General technical characteristics, essence of invention

The designs of the combined (inertial-filtering) gas separators are equipped with effective input nodes that perform functions of preliminary liquid separation and trapping of mechanical impurities, coagulators of fine dispersed aerosol and high-efficiency centrifugal, inertial and filter separating elements.

Comparison with world analogues, main advantages of invention

The estimated payback period of new gas-separators of inertial-filtering type – up to 3 years; in the case of modernization of existing separation equipment – up to 1.5 years.

Intellectual property protection status

11 patents of Ukraine for inventions and utility models were obtained.

Market demand

Invention can be applied to oil and gas processing plants, as well as in chemical industries where separation of gas-liquid streams is required.

Status of invention

Invention is implemented at industrial enterprises.