Purpose and Scope

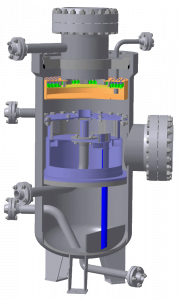

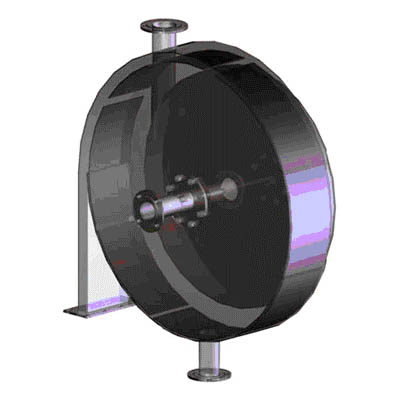

Traditional mass-exchange column equipment is characterized by significant mass-size characteristics and high cost. The device is designed for absorption, rectification, extraction and other heat and mass exchange processes. The rate of mass exchange processes per unit volume of VSCMED increases by an order in comparison with that one of similar column devices.

Main Characteristics and Essence

The vortex spray countercurrent mass exchange device allows reducing the material consumption of mass-exchange equipment by 5–7 times.

Specifications:

- Hydraulic resistance of the device 2.4 kPa

- Gas purification 98–99%

Benefits

For the first time in the real design of the mass exchange machine, countercurrent vortex motion of gas and liquid (drip) flows is realized, which allows you to achieve several stages of concentration change in one spraying stage and to replace the column equipment, which consists of 6–10 plates, with one apparatus.

Intellectual Property Protection Status

Five patents of Ukraine for invention and utility models are received.

Market Demand

The device can be used to carry out mass exchange processes in gas-liquid systems at chemical, oil and gas processing and food industries.

Readiness for Operation

The device is successfully used in several industrial enterprises.